CASTING

Based on its long-standing experience and knowledge in the field of composite processing, the Gutmann company has adopted its own unique approach. As early as 1991, we developed a unique casting process using "Buloxiet". As a result, in order to meet our specific requirements we decided to design fully computer-controlled blending facilities under own management. Why? Well, from the storage facilities to the blending system to the injection pump, nothing can be left to chance.

n this carefully controlled environment, we now produce standardised parts with dimensional tolerances of 0.05%.

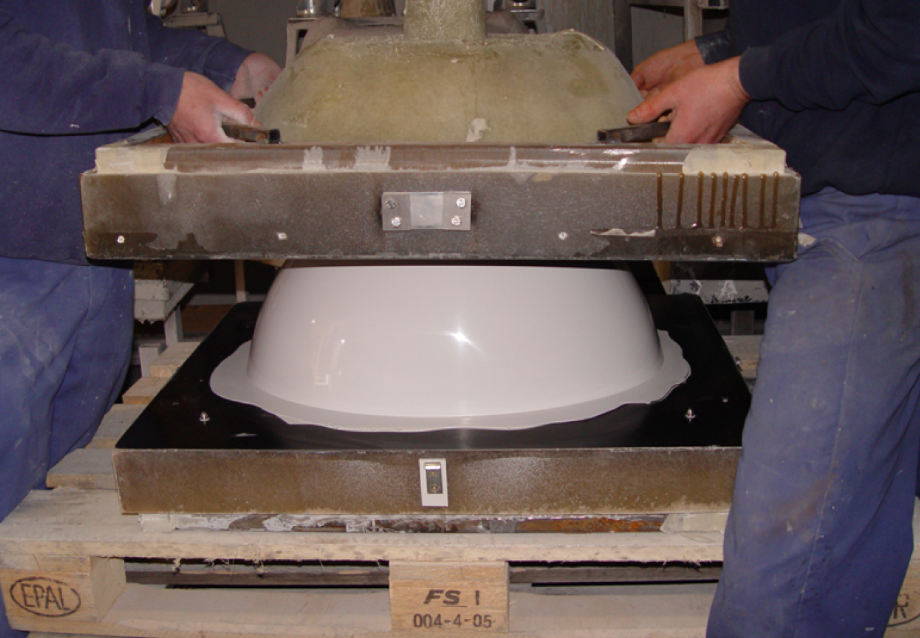

The following images show our production process.

Application of the mould release agent and buffing.

Coating of the mould and counter-mould.

Closing of the mould.

The casting/injection process.

Removal of the mould.

Preparation, trimming and drilling for finishing.

Following the final checking and sanding of the items, they are either polished to produce a high-gloss finish or honed to obtain a smooth mat surface.

All our workers are trained in-house to guarantee the highest possible quality.